Wet Processing Technology is a specialized field within textile engineering that focuses on the chemical treatment and finishing of fabrics to enhance their appearance, texture, and performance. The 4-year Diploma-in-Engineering in Wet Processing Technology prepares students to manage various processes involved in dyeing, printing, and finishing of textiles, which are essential for producing high-quality garments and textile products.

This program provides both theoretical knowledge and practical skills to handle modern wet processing machinery and environmentally sustainable chemical treatments, ensuring that graduates are ready to meet the challenges of the textile industry.

Key Learning Areas:

- Textile Fibers and Fabrics – Understanding different types of natural and synthetic fibers.

- Dyeing Technology – Techniques and machinery for fabric dyeing, including batch and continuous processes.

- Printing Technology – Methods such as screen printing, rotary printing, and digital printing.

- Finishing Processes – Chemical and mechanical finishing methods to improve fabric properties like softness, water resistance, and wrinkle resistance.

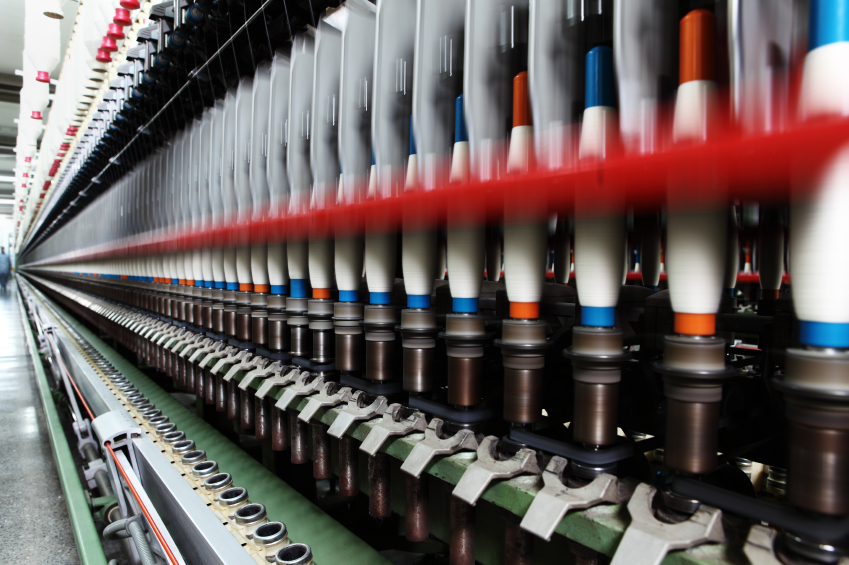

- Wet Processing Machinery – Operation and maintenance of dyeing machines, washing machines, and finishing equipment.

- Chemical Application and Control – Use of dyes, pigments, and auxiliary chemicals with quality and environmental considerations.

- Quality Control in Wet Processing – Testing and ensuring fabric quality and color fastness.

- Environmental Management – Wastewater treatment, pollution control, and sustainable processing practices.

- Process Optimization and Automation – Using technology to improve efficiency and reduce environmental impact.

Career Opportunities:

Graduates of Wet Processing Technology can pursue roles such as:

- Wet Processing Technician

- Dyeing and Printing Supervisor

- Quality Control Officer

- Textile Chemist Assistant

- Production Manager in Textile Mills

- Environmental Compliance Officer in Textile Industry

- Research and Development Technician

They find employment in textile dyeing and finishing mills, garment manufacturing companies, textile chemical companies, quality assurance labs, and environmental agencies focused on textile pollution control.

Why Choose Wet Processing Technology?

Wet Processing Technology plays a critical role in the textile and garment sector, which is a major contributor to Bangladesh’s economy. This field offers exciting opportunities for those interested in combining chemistry, technology, and environmental management to produce high-quality textile products sustainably. Graduates become key professionals in driving innovation and eco-friendly practices in the textile industry.

Number of Credit: 158